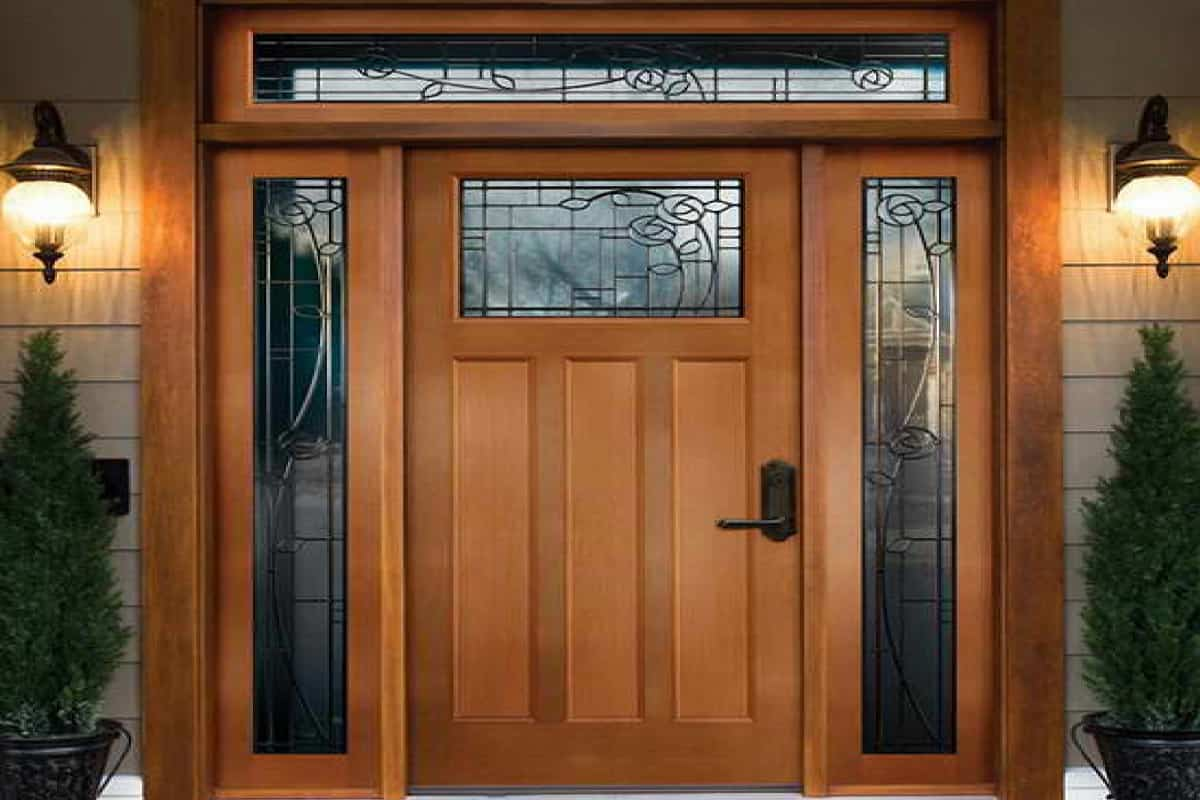

Price and purchase of MDF interior door trim + Cheap sale

We’ll demonstrate how to construct trim for interior and exterior door types and windows mostly of MDF

We won’t demonstrate how to create the base since most home improvement stores and lumberyards have at least one kind of primed, broad baseboard

However, if you’d like, you may also create your own baseboard using the methods we’ve provided here

MDF that is 1/2 in

and 3/4 in

thick, as well as some 1×3 timber that may be painted, are required for this project

We advise using wood for the stool instead of MDF since it can handle some moisture from condensation on windows

Although poplar, birch, and maple would also work well, we utilized pine

Using your cutting list, you can calculate how much material you’ll need, but as a general rule of thumb, you can cut the components for four to five windows from a single 4 x 8-foot sheet of MDF

MDF is cumbersome, and whole sheets are difficult to handle

At the home center, request that the sheets be split in half lengthwise

Remove any leftover nails from the door and window jambs and pry off the old trim

Sand the face of the jambs smooth if there is a paint or finish ridge to make room for the new trim

The doors and windows that require another trim should be listed

After that, take a measurement of the distance between the jambs and record it in your list

The first step after removing the old moldings is to measure each opening and make a purchasing list and cutting list

It’s simple to make the cutting list by just increasing the width of the apertures if you’re cautious to complete the arithmetic correctly

We provide how much to increase the width within the jambs for each component of the apron, stool, and head casing components in the cutting list we gave for a window

Because you’ll be using fractions, the math might take a while

Consider downloading a building calculator software for your smartphone if you need assistance with arithmetic while trimming out many apertures

To determine how many feet of each trim part you’ll need, use the list of components you generated

The MDF sheet should next be cut into the appropriate number of strips

To account for waste and errors, it’s a good practice to round up your totals by roughly 20 percent

Cut these strips to the appropriate lengths using a miter saw

Make sure to provide a matching window or door number to every component on your project

Rips MDF strips using a table saw while using your cutting list as a reference

Wear a mask and, if at all feasible, relocate your cutting and routing activities outside since cutting MDF generates a lot of fine dust

Put an exhaust fan in the window if you must cut inside

A port for attaching a vacuum hose was present on our router

If not, you may be able to purchase an attachment that will work with your router

Use a miter saw to trim the components to length after tearing them

As you proceed, label the components to prevent misunderstanding later

Make careful you sand the MDF strips smooth if your table saw leaves saw marks around the edge

The router bits’ guiding bearings follow the edges, and if they are uneven or bumpy, the resulting won’t be smooth either

Locate a large, level work table so you can fasten things to it

As previously shown, attach a stop and a backer board to the work surface

Provide sure the trim has a little overhang to the work surface to make space for the bearing that guides the router bit

To keep the trim in place and provide the router a flat surface, sandwich the trim part between pieces of MDF

Align the ends of the trim piece and the two MDF strips with care, ensuring sure that the ends extend slightly beyond the work surface to provide an area for the bearing on the router bit guide

the strips to the work surface using screws

To keep the trim piece in place, add a stop behind it

To form the end of the trim, move the router across it from left to right

The form should then be routed on the other end after flipping the trim end to end

Two 2×4 lengths should be cut to the same (3 in

) width as the bottom window apron before being joined together with screws

The bottom window apron section should be clamped to the 2x4s after toe-screwing them to the work table

With the router, you can now effortlessly shape the long edge and both ends

As you route the thin ends, the 2x4s provide the support required to keep the router level

The most important instruments for this project are basic router bits

Simple router bits like a cove, round-over, and classic ogee may be used to shape the edges of affordable MDF to create the components for a traditional trim makeover

Gather the four head casing components and set them out on your work table

Apply adhesive to the edges that will be joining, then use 1-1/2-in

trim nails to secure them

Make careful to position the components so that the end reveals (overhangs) are straight before nailing them together

After attaching the stool to the apron assembly, glue and nail the top window apron to the lower window apron

Ensure that the end overhangs are uniform

To identify the trim edge and create a 3/16-in reveal, mark each corner of the window with a pencil 3/16 in inside the jamb

On brief lengths of masking tape, indicate the window’s center and the assembly’s center as well

Align the reveal markings on the stool with the center marks

After that, fasten the assembly in place by nailing through the apron and into the wall frame under the window

A casing piece should be cut an extra inch or two long

Place it on the stool and make a reveal mark on the top

With care to maintain a uniform reveal from top to bottom, snip the side casing to length on a miter saw and fasten it in place

Use the same procedure to mark, snip, and set up the casing on the other side

Make sure the fillet equally overhangs the side casings as you center the head casing assembly over the window

Then drive a nail into the wall frame above the window through the head casing assembly

Plaster blocks placed under the side casings of doors and other openings will complete the traditional appearance

By joining strips of MDF that are 1/2 in

thick and 3/4 in

thick, you may create the 1-1/4 in

thick plinths

Create a cove on the top edge after that

To create a little offset where the casing sits on the blocks, make the plinths approximately 1/4 in

broader than the casing

How simple it is to install the trim will amaze you

Nail on the base plinth before beginning to trim the door or other apertures

These plinth blocks were created by joining pieces of 3/4-inch and 1/2-inch MDF with glue and routing a cove shape into the top edge

If you need to finish numerous doors, create a number of blocks by first cutting 1/2-in

– and 3/4-in

-wide strips

We constructed our blocks 7-1/2 inches tall and glued them together using MDF, which is a bit broader than that height

Once the adhesive has dried, trim the edges of the strip to the proper width using a table saw

The cove will then be routed along one edge

Cut the blocks to a final width of 4-1/4 inches

By cutting and attaching the side casings and nailing on the head assembly, complete the door apertures in the same manner as the windows

The baseboard installation and painting are the only remaining tasks after that