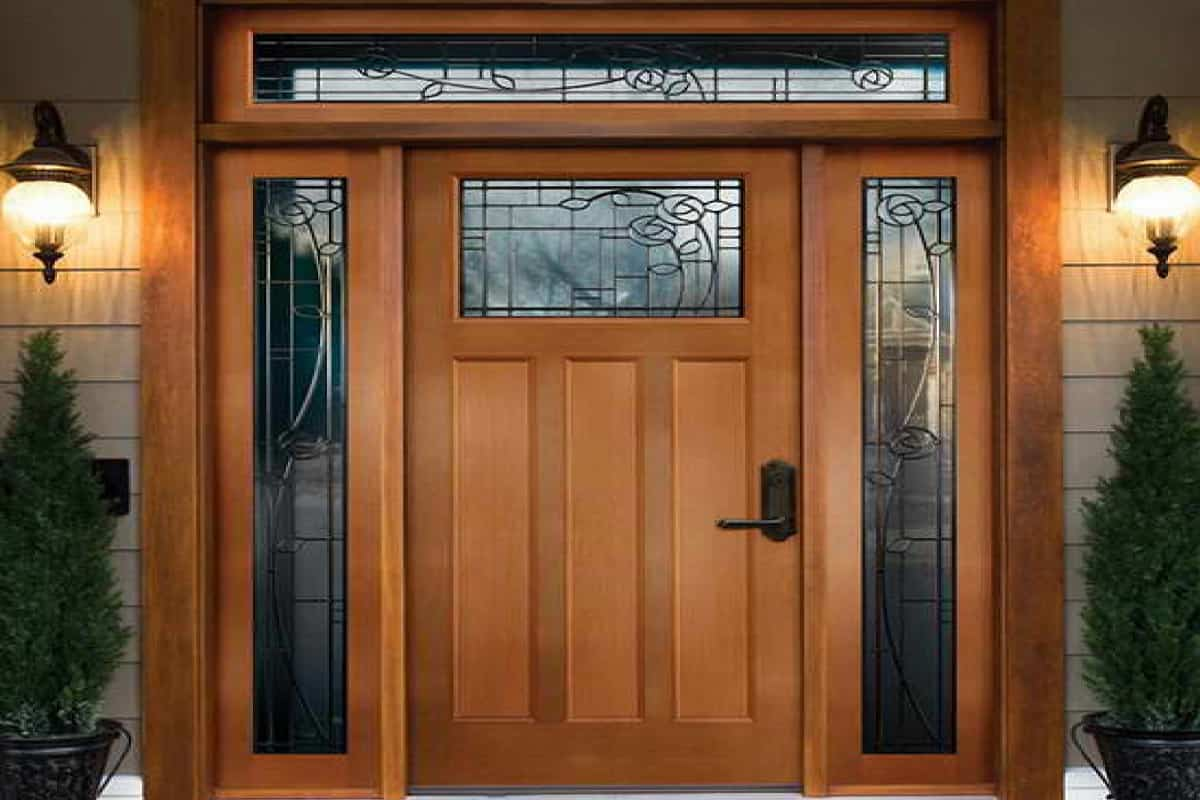

fire door installation regulations

Any entrance door that connects a garage to a home should after an accurate installation process, according to our team of suppliers, be a fire door

The door can resist and stop heat and fire from breaking through for at least 20 minutes, according to its minimum rating

Fire-rated doors are pre-hung, which means that they are delivered as a complete assembly with the door, jambs, sill, and brick molding

A person can help you raise and place a fire-rated door since they are quite heavy, regardless of whether they are constructed of steel or wood

Make sure the rough hole in the wall frame is big enough for the door’s height, breadth, and depth measurements before installing it

The instructions that came with the door provide a printout of these measurements

Put a lot of polyurethane caulk beads beneath the door sill or on top of the frame where the door sill will be placed

Apply a bead of polyurethane caulk along the brick molding’s reverse side

Place the door in the rough aperture by lifting it into place from the outside

Push the door open so the brick molding is flush with the wall facing the garage

Prepare the hinge-side jambs next to each hinge by drilling 1/8-inch holes through them

While facing the door, place the level along the hinge-side jamb to make sure it is straightforward, backward, and left to right

Each pre-drilled hole should have a 3-inch screw driven through it and into the wall frame

Never completely tighten the screws

Just above and below the screws, place tapered shims

When required, move the shims in or out to fill the gap between the jamb and the wall while making sure the jamb is absolutely plumb

Fix the screws firmly

The screw heads need to be a little below the jamb’s surface

By first scoring the shim with a knife, then snapping the waste off at the scored line, you may remove extra material from the shims

In the same general places as you did on the hinge-side jamb, pre-drill holes in the latch-side jamb

The same as you did on the hinge side, check the jamb for plumb

Measure the distance between the door frame’s top left and bottom right corners

Then calculate the distance between the bottom left and top right corners

For the door to be square, these two measures must be perfect duplicates of one another

Through the holes that have already been made in the wall frame, insert 3-inch outside screws, but do not fully tighten them

Apply tapered shims as required to fill the space between the wall frame and the jamb, then fully tighten the screws

The screw heads need to be a little below the jamb’s surface

Take the shipment or transport latch out of the latch pocket

As directed by the manufacturer, attach the latch kit, door handle, and deadbolt if one is included

Check that the door fully shuts on its own and locks shut as it should thanks to the self-closing latches by opening it

Adjust the spring tension in the latches in accordance with the manufacturer’s instructions if the door does not latch close on its own

Since there are various styles, different adjusting methods may be used

Use a nail gun to drive finishing nails through the brick molding, and then a caulk made of polyurethane should be used to seal the joint where the brick molding joins the garage wall

In order to fill the space between the door jamb and the wall frame, use fire-rated expanding foam

Perform this inside the home

Trim the extra foam with a utility knife after it has completely hardened so that it is flush with the jamb’s edge

To fill the space between the border of the jambs and the inner walls of the home, measure and cut internal trim

Utilizing a miter saw to cut the molding and finishing nails to attach the trim

Cover the screw heads in the jambs with wood putty that may be painted or stained

When the putty has dried, sand it flush before painting or staining it to match the other jambs

It is the owner’s and the installer’s obligation to utilize installation techniques and materials that comply with local building requirements if a fire rating is needed for both the door and the framed opening

Place the door in from the inside

Affix the bottom of the door to the opening’s bottom, and then tilt the top into place

Insert one 1-1/4″ nut to secure the door in the middle of the opening’s sides “screw into a hole at each of the upper corners of the installation fin

As the steel frame assembly is completed, this will keep the door in place

Square and Plumb Door With a level, examine the hinge side jamb for squareness and plumb in both directions (right to left and inside to outside)

Add screws to the installation holes for the nail fins to make any required modifications

Continue until the door is square and plumb on the lock jamb

Secure the door using 1-1/4 “screws in each of the mounting holes for the nailing fins

Install the closure pieces between the weld plate and the stop return on the outside side (the side opposite the nailing fins)

Start at either end of a closure piece

It may be required to lightly push on the frame to enable the closure to pass through the weld plate and halt return

Use 1-1/4 screws to secure the head closure and both jamb closures to the wall after the clearances are established (pushed flat against the wall)

Verify that the panel’s bottom weather strip has enough contact with the threshold

If there is a dollar bill or piece of paper above the adjustment screws, close the door on it

A little amount of friction must be felt while removing the paper, indicating a proper seal

A threshold adjustment is necessary if there is a poor seal

For every adjustment screw, repeat

To ensure proper contact with the door sweep, the height of the normal threshold may be modified as required

Use a #2 Phillips screwdriver to spin the adjusting screws clockwise to lower the border or counterclockwise to increase the threshold after removing the screw cover covers as required

Corner seal pads should be placed in each corner of the framework tightly against the top of the threshold, with the thicker part of the tapered pad placed against the frame weather-strip

Remove the backing paper from the corner seal pads