what is steel door + purchase price of steel door

With advancement in technology of production machinery, different types of metal door such as hollow and insulated, of various material types appeared in international markets

After the invention of more powerful and heavier manufacturing machines and foundation of more facilitated factories, the velocity of production was dramatically increased and not only special and governmental buildings, but also ordinary people could utilize doors of different species of metal for their houses

Seemed like it was the time to substitute the old wooden doors with the ones of steel, iron and other kinds of metal

producers were able to cut steel and other types of metal sheets into desired shapes much faster than before, to make all types of steel doors for different type of buildings and various usages

Day by day, there were also new threats against properties and buildings, objects inside them and even doors themselves; in addition to burglars, natural disasters like flood, fire outrage and even earthquake necessitated the doors and their frames to be built waterproof, fireproof and solid enough not to break and block the way of the people fleeing during an earthquake

First, manufacturers decided to use raw metal to protect the latter against the threats, but more protection equaled less beauty

The material these doors are made of is of the essence, too; the rarer and costlier the metal type, the more luxurious and more expensive the door

hollow metal door types

As you may have thought about it, if a metal door is full and solid inside, it would be too heavy to use; there hollow types come into being

If a door is stuffed with thick sheet of steel, it would put a lot of unsustainable pressure on the framework and the hinges

The only places where stuffed doors are used conventionally, are banks or depositories where protection level has to be beyond imagination

Hollow metal doors are used mostly in industrial and commercial areas and also institutions; schools, universities, factories, companies, sport complexes and etc

these doors are made of a steel framework and steel layers laminated to each side

In addition to holes and slots carved for hinges and handles, there should be a pocket to host the lock system in it

There are 4 main kinds of hollow doors of metal

‘Flush hollow doors of metal’ have flat and solid sheets covering each side and they are the most common types of hollow metal doors

If this type of door has a decent core material, it can resist fire up to 3 hours

Hollow doors of metal with windows; this model has at least one window cut out of the door for sake of better visibility range and more incoming sunlight

However, there are certain proportions defined for this glass and it also has to be of certain material to provide sufficient protection for the property

Clients can order these doors with louver windows instead of glass ones to let some air flow in

Hollow metal doors with panels; when the door is decorated with (commonly 6) panels with different colors and drawings on its both sides, we call it a paneled hollow metal door

The mentioned models are more beautiful than the other ones

Graintech hollowed metal doors are the ones without any wood in their structure but back in the factory, producers stain them the way they look like wooden doors

They do this for sake of art and beauty along advantages of a full metal door

types of doors

Hence doors are nowadays produced in many factories, in many countries and for many usages, the ones especially designed for modern homes are expected to be offered in several models

In this paragraph, we are going to introduce a few of them which are less discussed

Dutch doors are the first group in this regard; a Dutch door or double-hung door is a horizontally split type; the upper half can be opened and closed while the lower half of it remains shut

This model is suitable for both interior and exterior environments in which little children or some animals are kept and you need to look after them

Pocket doors are one of the sliding types which slide into a flaw curved inside the wall next to them

They can also slide up and be placed on a certain track on the ceiling

Pocket doors are a good choice for the ones who would like to divide a room into two rooms for some reason

Pivot doors which are manufactured with a vertical bar (axis) to rotate about and are offered with and without a stopping mechanism

Battened doors are a good-looking group made of standing boards attached to ledgers placed horizontally

The battens of these doors are up to 18 centimeters wide and 3 centimeters thick

The thinner the battens, the more beautiful the door

Louvered doors, as we can expect them by their name, are designed to be iconoclastic

Enhanced with vertical flaws, they offer the user a sufficient air ventilation which makes them a brilliant choice for people living in tropical regions and also for buildings where a decent air flow seems vital; like power stations

metal door material

Lasting about ten years more than fiberglass or wooden ones, a metal door made of a decent material type such as galvanized steel and carbon (stainless) steel gives you whatever you need in terms of strength, protection and durability

As a mix of carbon and iron, stainless steel contains a certain amount of chromium element

The mentioned complex in addition to some nickel makes the door heat-resistant and corrosion-resistant

Moreover, stainless steel is well-known to be nature-friendly and recyclable

Galvanized steel is another type of steel which is invented to cover the surface of the metal not to let it get corroded

To provide galvanized steel, producers cover the steel with a layer of zinc; thickness and amount of this zinc could be customized due to different factors

Galvanized iron for doors and roofing in company with corrugated galvanized sheet for doors and roofing are of the same group of products

This zinc coating also provides more beauty and shine for the steel panel

Among methods of galvanization, hot-dip galvanization is the most famous one which would be accomplished with embedding the iron or steel sheet in a bath full of molten zinc at about 450 Celsius degrees

hollow metal door

Both manufacturers and clients may rather prefer a hollow metal door for their convenience, light weight, enough protection and sufficient durability; especially the ones made of stainless and galvanized steel

Manufacturers of hollow metal doors make these doors with a core within them; the core forms the main inner structure of the door and fills the blank space between the main panels

5 standard hollow metal door cores which have been produced so far are going to be discussed below:

Honey comb door core which gets its name from its special hexagonal structure which looks like that of a honey comb where actual bees live

Producers who make doors with this type of structure, harden and reinforce it with a specific kind of resin

Honey comb core is a durable structure which is common for interior doors

It can resist heat (of fire) for three hours

Polystyrene is a slab layer of foam taking place inside the core

Doors with this type of core can bear heat of fire for three hours and are suitable to be used for exterior gates

Polystyrene core doors are more insulated than the ones with honeycomb structure

Unlike Polystyrene, Polyurethane is injected inside the core of the door and grows to the point it fills all the empty spaces between the door’s panels

Although these doors can’t resist fire for a remarkable amount of time, but they are totally more insulated than the previously-discussed models

Steel stiffened core doors are the ones with steel sections (channels) in them, filled with insulation

The doors with such core are useful for clients who mind quietness

Mineral core doors then, are a suitable choice for the clients who intend to provide their property with a high and definite ratio of protection against fire

Doors with a sheet of mineral board within them don’t even let the heat of the fire on one side, pass through the door to the other side

steel door finishes

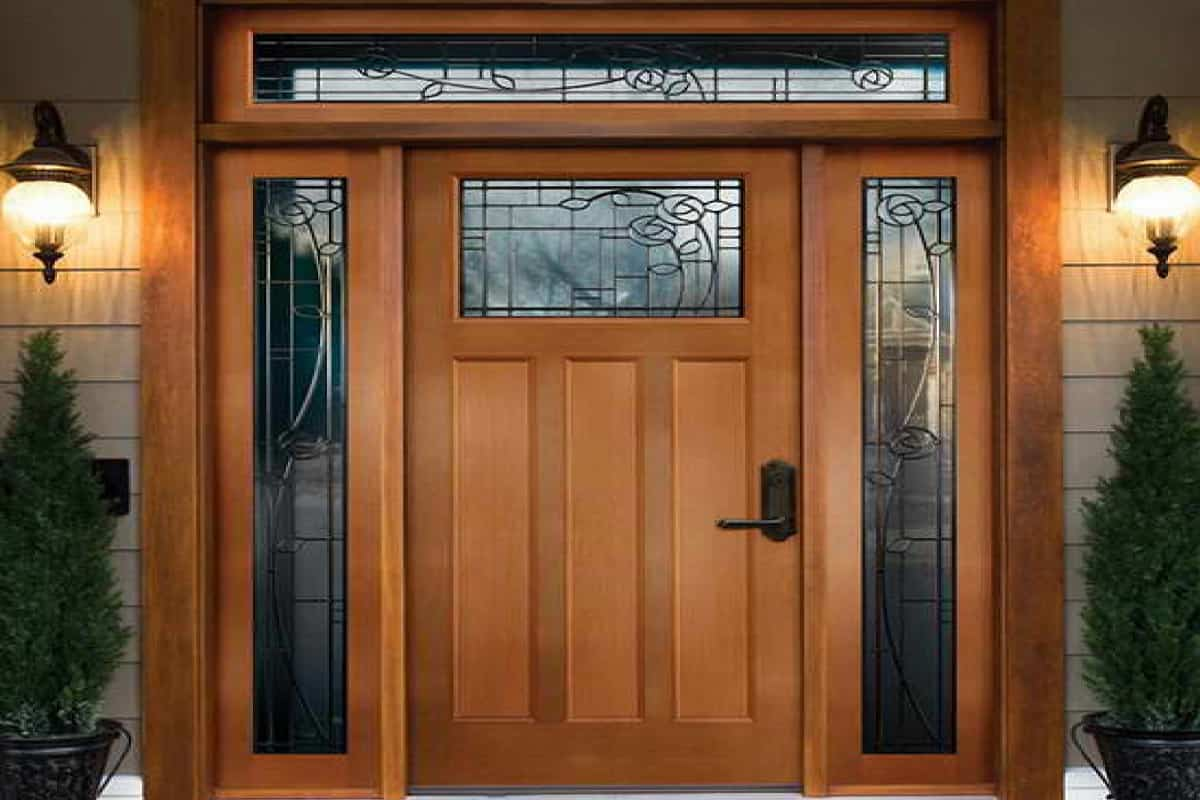

At the same time with invention of wood finish steel security door, manufacturers decided to coat their steel doors with different finishes, too

Seldom people would roll their sleeves up to fix their injured door or to color their front door on their own

But approximately everybody agrees that the coating of the door of the house is one of the most prominent factors of both interior and exterior façade beauty

Nowadays, there are various finishes for steel door surfaces but the most famous ones are powder coats

In this method, they bake the door with the powder poured all over its face in an oven at 425 degrees

The heat ensures that the powder is stuck to the surface forever

Powder finishes can also be decorated with popular designs and colors to fit in every house

There are also matte black and bronze powder coatings to be used the same way

Whether matte or shiny metallic, the powder coatings have to be humidity-resistant not to let fog and moisture through to make the door corroded; they also must be heat-resistant to the point fire cannot melt them down

If this happens, the door has to be carried back to the factory to be coated again

Wooden finish steel doors are categorized as steel doors too, even though they just look like wooden doors

They are consisted of a steel sheet within a wooden framework with extra hinges and anti-theft lock system

steel door manufacturing machinery

Just like others, steel door factories manufacturing all types of metal doors mentioned and discussed above have one or more long production line consisted of various machinery receiving simple flat sheets of iron, stainless steel or galvanized steel and the rest of the raw material such as coating powders and accessories including hinges, handles, lock system, openers, pins, cylinders and etc

accomplishing a lengthy and detailed process on them and manufacturing many types of doors in different models, designs and colors

The first machine to play its role is the ‘door frame roll forming line’; the combined machine is consisted of in-line rolls tossing the door forward and a cutter part; the cutting blade works with at least two hydraulic bars strong enough to amputate (averagely 1 millimeter thick) steel frameworks accurately into the desired shape and the operator of the production line has to make sure it works accurately

By the way, the speed and other features are manually adjustable

Steel door production lines have been designed in several models so far, such as: pedal plate punching, piling role forming line and door panel forming line

All the above, receive the panel, level it, punch the necessary holes in it, emboss the coatings on it, bend wherever necessary, form wherever necessary and cut the material off from designated points

Manufacturers of metal door production machines have also designed hydraulic press machines for making beautiful desired skins

Producers can give the machine their favorite designs, place the door panel inside and the giant mouth gets closed, stamping the drawing(s) on the face of the steel door

The depth of the drawings is (and must be) adjustable too, because if the door is carved deeply, the drawings, thinning the thickness of the door, can change to a weakness point rather than beautiful features and work against the owner of the property rather than in his/her favor

Equipped with all the machinery above and enjoying every single feature discussed in this article, our great team of professional suppliers and experienced negotiators is ready to establish an enduring line of trade with you, no matter which country you represent