The panel doors often referred to as wooden rail and stile doors, have been used for internal areas since they first entered the market in the 18th century. But how? They are built of components (rail, stiles, and infill panels), which when combined make a highly sturdy, long-lasting door, and are still as popular now as they were two hundred years ago.

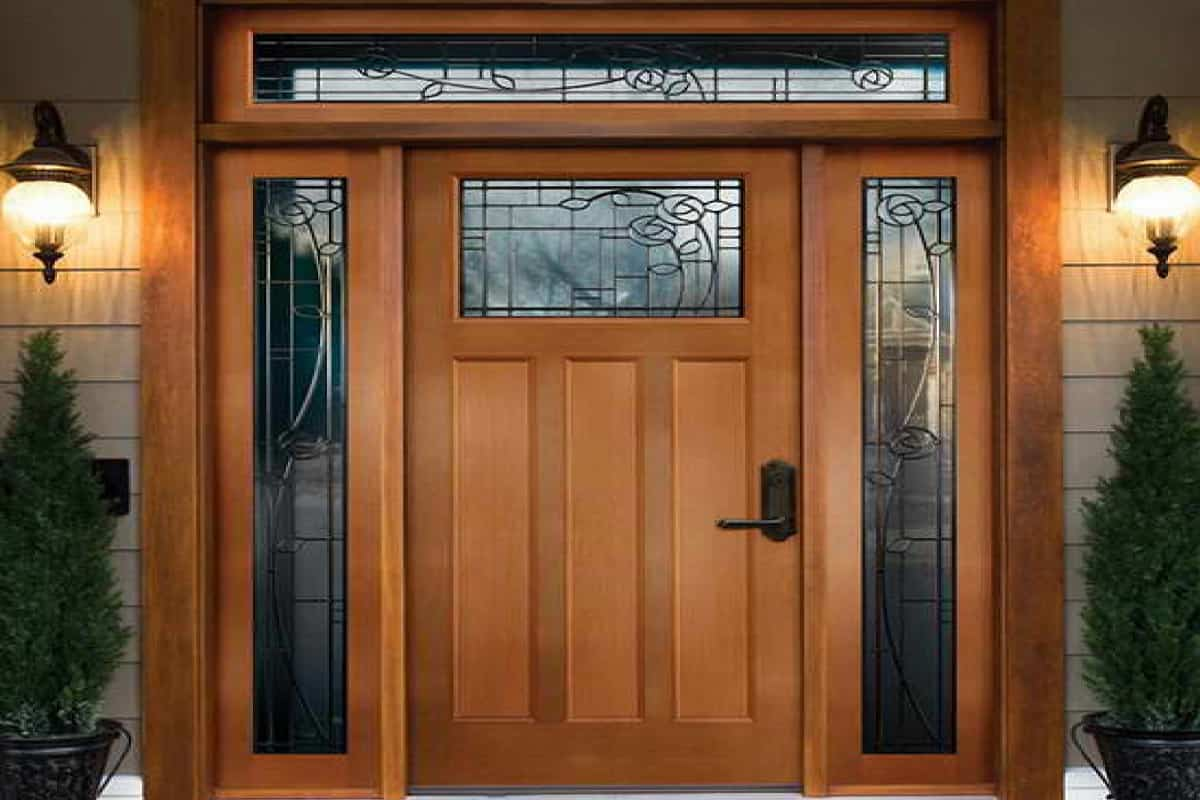

Despite being more often constructed of wood, panel doors may also be manufactured in steel, aluminum, or composite materials. A four-panel or six-panel door, which complements nearly any decor, is the most common design. You may choose a glazed version if you want the light to enter your house.

Panel doors employ a straightforward construction technique with the panels raised or recessed into a solid or composite door. Simple or elaborate stiles, rails, and mullions surround them.

Due to its organic shape, wood expands and contracts with changes in humidity, but panel doors are built to withstand this movement.

The vertical outer stiles, which are responsible for stiffening the wing and preventing the doors from buckling, maintain the door straight so that it operates well. The central stiles divide the area to allow the panels.

The rails are horizontal lengths that frame the panels in addition to keeping the outside stiles parallel. A top, middle, and bottom rail is included on every panel door to aid in stiffness. The vertically oriented mullion creates separations between the various door panels. A glue of industrial strength is used to join the door’s components.

Excellent insulation and soundproofing characteristics may be found in panel doors. They are ideal for high-traffic areas since they are quite resilient, need little upkeep, and can sustain years of usage.

Because panel doors are so sturdy, it is almost difficult to punch a hole through them, providing excellent security.

Speak with the professionals at Door Stop if you’re thinking about panel doors. Have you had a chance to read our testimonials on the internet? Because of the quality of our doors and the service we provide, our clients keep coming back to us. There is nothing stopping you from purchasing that new door today.

Plank doors and transitional doors, which emerged during the Renaissance, were replaced in terms of design by paneled doors, also known as stile and rail doors. This clever construction technique cleverly enables the panel to move fluidly while the stiles and rails of the framework stay secure, overcoming the wood’s inherent inclination to shrink and expand.

Paneled doors are more intricately made and need more expertise to make. Raised panels, contoured moldings, and solid or veneer wood with lovely graining are some examples of its design improvements.

Paneled doors’ characteristics

Panels may be raised or flat.

Inside a wooden frame made of stiles and rails, the panels “float.”

Various architectural styles need different molding profiles.

Stiles is vertical planks.

Railings are horizontal planks.

The placement of the molding profiles on the panel varies, in addition to their forms. They may have a straight edge to the rail and stile and sit flush on the panel. Additionally, they sometimes lip over the rail and stile before settling on the panel with a cut-out notch (or rabbet). They may also be positioned below the face of the stile and rail and utilized as sunk molds. These techniques all result in various looks.

The door, together with the window and roof, makes up the bulk of a home. It offers protection and cover. It provides ventilation and fresh air to the house’s different rooms.

It is a paneled door, sometimes known as a panel door informally and more frequently online. The most common kind of door used in homes since the early 1900s is a panel door. It looks nicer than battened doors and is stronger. The panel door may be built with 4 or 6 panels for the house’s visual appeal. They come with either inward or outward opening options. A panel door is built using panels, which are often formed in a pattern and inserted between the stiles and rails that make up the door’s outer frame.

Single panel doors have a frame made up of two stiles, a top rail, and a bottom rail. Double Two wooden panels make up a panel door, and the frame is divided into two pieces by a center rail or stile.

Three wooden panels, including two center rails or stiles, make up a three-panel door.

The four rectangular panels of the four-panel doors are divided into two larger panels above the central horizontal rail and two shorter panels below.

Six hardwood panels, three middle stiles, and four middle rails, which divide the frame into six equal-thickness portions, make up 6-panel doors.

Wood, plywood, veneer, blockboard, medium density fiberboard (MDF), asbestos cement sheets, glass, pre-laminated particle board, wire mesh, etc. are used to make the panels. By including grooves in the stiles and rails, the panels are secured. The panel door is also called the stile and rail door.

The stiles are continuous throughout their whole height. The stiles are connected to the top rail, frieze rail, bottom rail, and lock rail. More robust and larger in size than the top and frieze rails are the bottom and lock rails. The lock rail must be positioned such that its middle is 800-900mm above the bottom of the shutter. For lock and bottom rails, the minimum width should be 150mm, and for stiles, it shouldn’t be less than 100mm.

Tenon and mortise joints are used to link the stiles and rails.

One must be cautious while choosing the designs of panels to consider the panel’s material, thickness, and construction technique. When working with natural wood, the more joints you have, the more careful craftsmanship is required since poorly done joints and thin panels compromise the door’s and the house’s safety.

Wooden panel doors

The most popular wooden option for inside and external areas is panel doors. However, this does not imply that you must have paneled doors that match those of your neighbors. There are so many different paneled door designs that you may utilize to give your property a distinctive look.

A paneled door displays a certain sort of building technique. Paneled doors are created by manufacturers utilizing individual panels and frames. The master craftsmen claim that paneled door designs are a more opulent look than plank doors.

To combat wood’s propensity to contract and expand with the weather, this design was created. The many parts of the door enable one another to alter without harming the construction as a whole.

There are three primary features of paneled doors: the framework, the panels, and ornamental molding. These elements come in a variety of forms. The frame of the door is built using horizontal components called rails and vertical parts called stiles.

These doors also have inset panels or raised panel designs with various panel counts and shapes. Additionally, paneled doors have several molding types that distinguish them from one another. Some paneled door styles are solid, while others contain glass panels or “lites.” Some, like shaker panel doors, don’t have molding, keeping the style simple and understated.

True panel doors and molded panel doors are the two primary varieties of paneled doors.

True panels doors are built from solid materials and include frames and panel parts in their design. Molded panel doors have an internal core and skins or solid parts that are molded to resemble panels.

The oldest and most traditional form of a panel door is the wooden one. True panel construction employing solid wood of different sorts and molded door variants are both features of wooden panel doors. These wood panel doors come in a broad range of designs with panel doors for the inside and outside.

Aluminum is a lightweight metal that is used by manufacturers to make both interior and exterior panel doors. Instead of utilizing separate aluminum door panels and frames, all aluminum paneled doors are molded. Some aluminum doors have an internal core and external skins. Others employ glass panels that fit within metal frames.

Steel Panel Door: Compared to aluminum, steel is a heavier and more robust metal. Steel panel doors are molded as opposed to being made of separate components, like aluminum. On the outside of the home, steel panel doors are often used. Glass panel doors with steel structures are often used as outside doors, but some people also utilize them to designate inside areas.

Vinyl Panel Door – Vinyl or PVC/uPVC doors have proliferated in contemporary architecture. Polyvinyl chloride is used to create vinyl panel doors by manufacturers. These can withstand moisture, making them handy in places like kitchens and baths. These doors are a more affordable option than fiberglass, wood, and metal. However, they don’t endure as long.

Fiberglass is a sturdy material that is often used for external paneled doors, such as front doors. Fiberglass panel doors are molded as opposed to being made with fiberglass door panels and frames, like other materials distinct from wood. Exterior doors with fiberglass panels are strong and mimic the appearance of wood.

Panel Doors Made of Molded Wood and Composite Materials – These doors are made of a molded material that includes wood as a component. The majority of interior panel doors feature an internal core and an outside made of MDF, medium-density fiberboard, or particle board. These inner paneled doors are the most prevalent kind. MDF is not suitable for outdoor usage since it will deteriorate when exposed to dampness.

A solid structure may be seen in certain paneled doors. The majority of these doors are made of solid wood with distinct frames and panels. Others have molded door panel skins that cover a separate core in one continuous piece.

For molded panel doors, solid core and hollow core are the two primary core kinds.

Solid Core – Doors with solid cores have cores filled with various materials. Solid wood core (SCL) doors have a center that is filled with plywood or another composite wood product. They have filled a solid particle core (SC) feature center with a particle board.

Hollow Core – The hollow core of hollow core doors is made of cardboard honeycomb. This aids in supporting the door’s outer covering. Comparatively speaking, these doors weigh less than solid core doors. Hollow core doors are not the best option for soundproofing.

The earliest style of paneled doors is made of solid wood. Using a solid wood panel door has advantages, but there are also some disadvantages to take into account.

Pros:

Design: A typical style of paneled door is made of solid wood. As a result, there are many various styles from which to pick depending on the kind of property you have.

Natural Beauty – The exquisite color and texture of solid wood will instantly bring elegance and refinement to any house.

Solid wood is a sturdy material that provides effective sound and weather protection.

Cons:

Cost – Interior and exterior solid wood paneled doors are among the priciest door alternatives.

Care – To maintain the structural integrity of external solid wood paneled doors, regular maintenance including painting and staining is required.

Molded exterior and interior panel doors come in many different variations. Each has advantages and disadvantages.

Pros:

Cost: MDF molded panel doors are more affordable than solid panel doors. Molded steel paneled doors are the most affordable option for outdoor areas.

Variety – There are so many different molded panel door types available that it’s simple to choose one that matches your taste.

Sound insulation is excellent in certain molded panel doors, such as fiberglass doors and solid core doors. Homes remain more energy-efficient with the help of exterior fiberglass and steel molded panel doors.

Cons:

Durability – Compared to more solid panel doors, hollow-core molded doors are lightweight and less robust.

Hollow-core molded panel doors do not provide enough insulation against sound or the elements.

Common paneled door designs come in a wide variety. To provide you with ideas for usage in your own houses, we’ve compiled some of the most popular.

Six raised panels are included inside the stiles and rails of the 6-panel front door. Sunken edges with a center that is at the same level as the stiles and rails are referred to as raised panels. Some of the most traditional styles of panel doors are raised 6-panel doors. Both 6-panel interior and 6-panel exterior doors are available.

Each panel on double entrance doors is two panels. These doors have a recessed panel, and the inside frame is framed with ornamental molding. As a result, the door has an elegant appearance. Additionally, there are glass side panels on the entrance door to let in more light.

Popular garage door designs include paneled garage doors. Glass and solid-material garage door panels are included in this design. The garage’s straightforward form blends nicely with the flat door panels. There are also garage door panels made entirely of glass, which provide a more contemporary look.